Using BEX to measure 3D Surface Roughness from X-Ray Computed Tomography (XCT): applied to a Dental Artefact

- 3D X-Ray Computed Tomography (XCT) is widely used in medical imaging and increasing used in additive and traditional manufacturing, due to its ability to provide high quality imaging for complex 3D components.

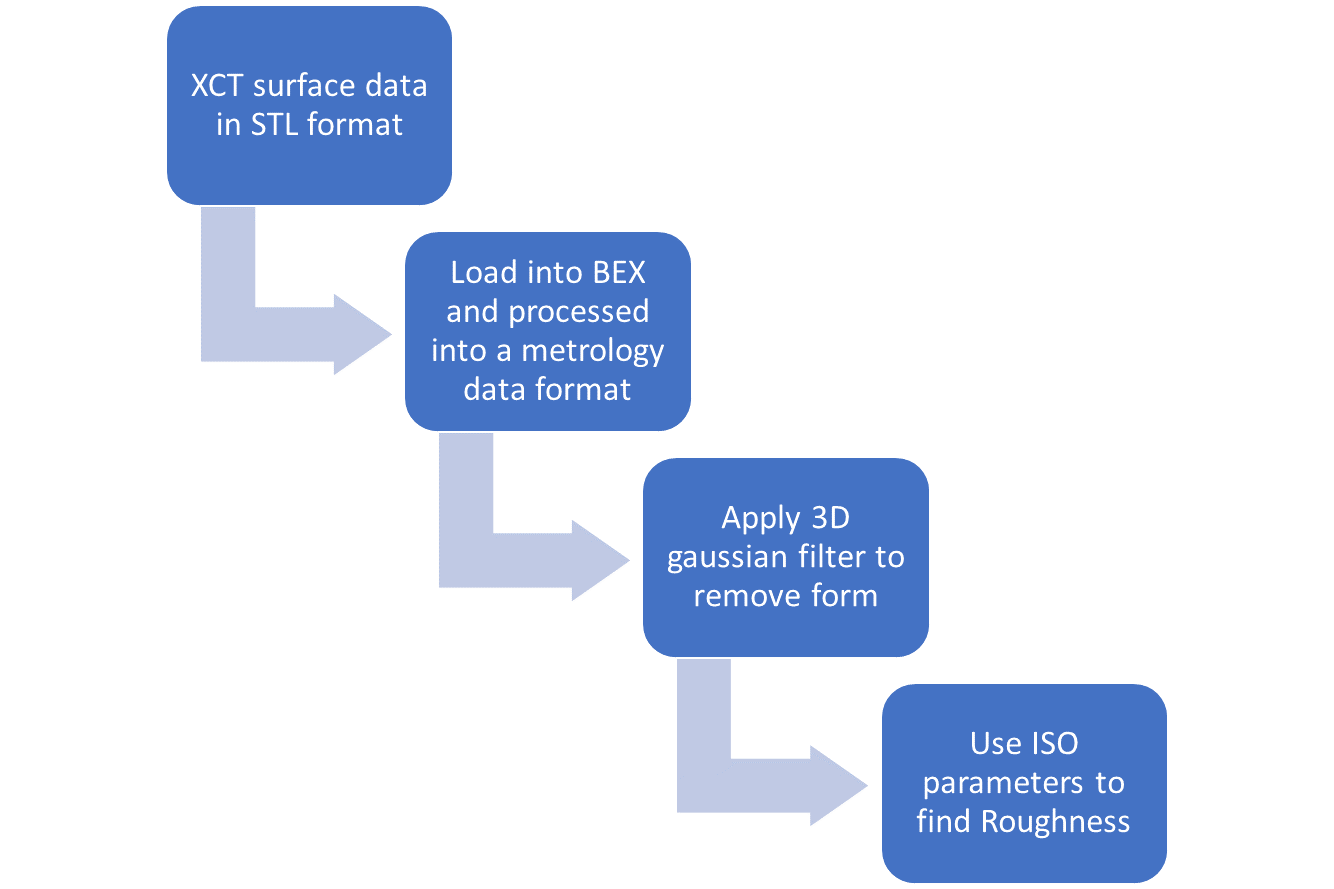

- The Challenge – To apply XCT data in surface metrology software BEX; and to process and extract information from XCT to measure the roughness of a complex natural surface.

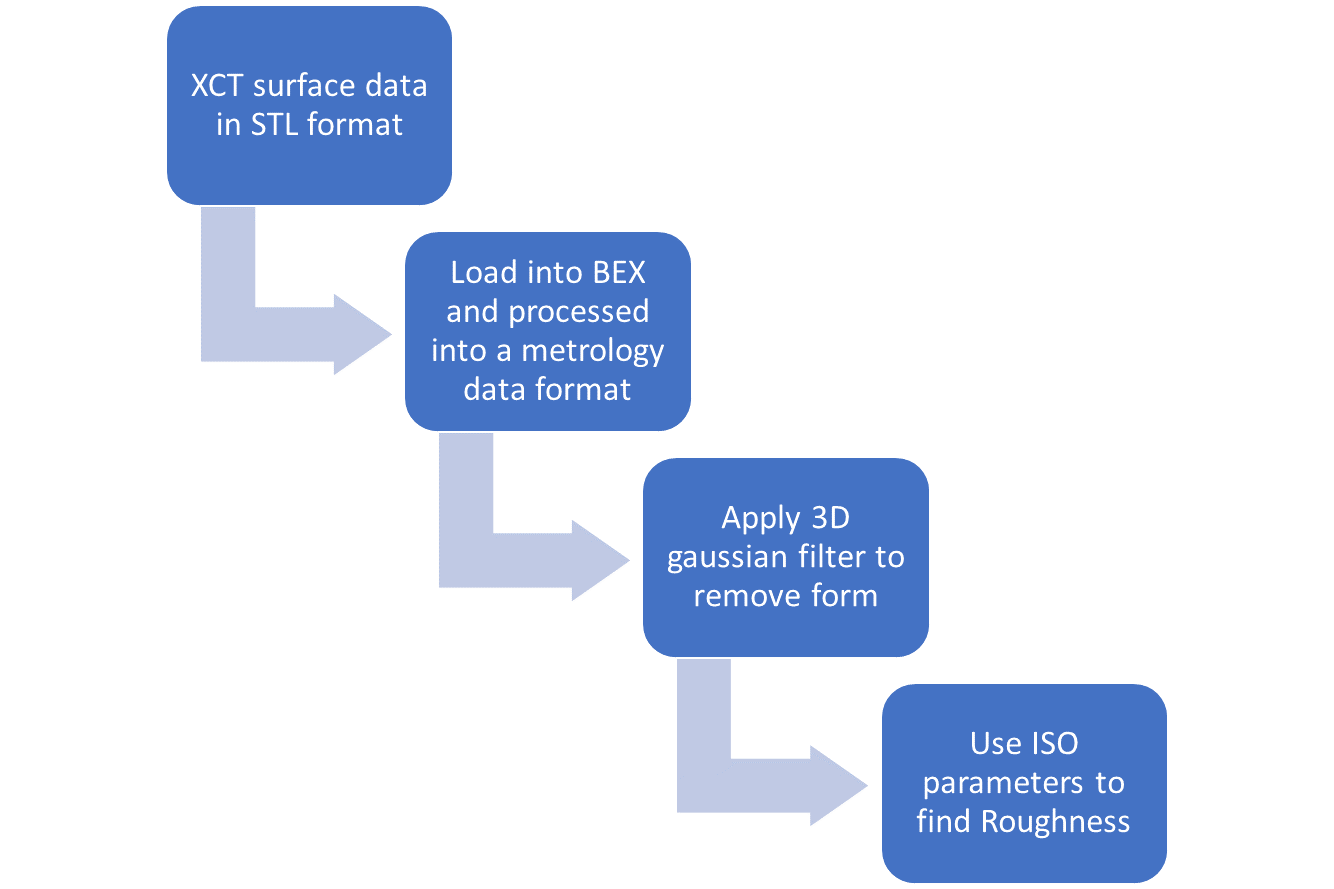

- The Solution – TaiCaan Technologies’ powerful surface analysis software BEX is used here to load the XCT STL data. It is then processed in a newly developed toolbox in BEX, where standard ISO surface parameters can be used to define the roughness of the surface.

- This application is a joint study with the UK’s National Physical Laboratory (NPL) and the University of Southampton, where a natural dental sample is scanned using XCT and then processed using BEX. TaiCaan Technologies XYRIS 2020 H confocal surface scanning system is used as a baseline to validate the processing BEX for XCT data. A similar roughness is found through a side-by-side comparison.

Introduction

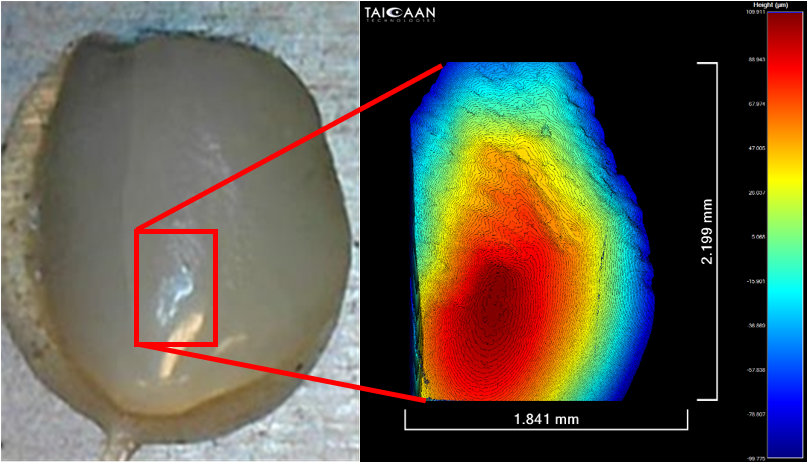

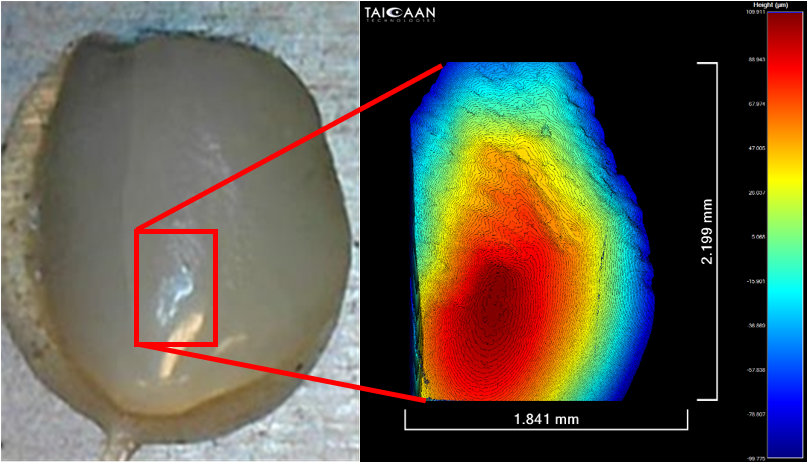

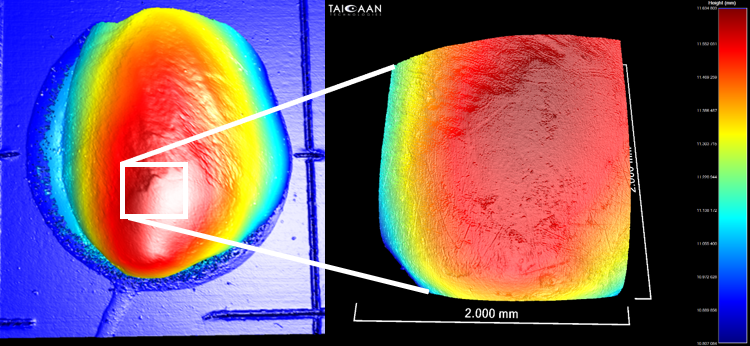

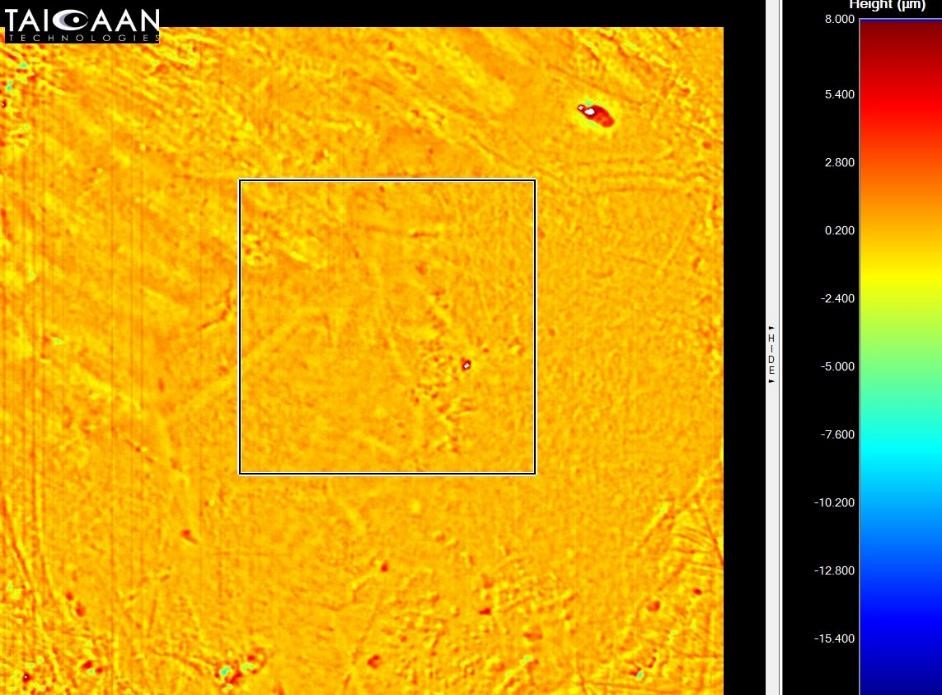

In this application a dental surface shown in Fig.1 has been measured using XCT. The XCT surface data is in a point cloud format (STL). In this application the STL data is loaded into BEX and processed using the BEX toolbox to a standard metrology data format allowing ISO surface parameters to be used to define the surface, as shown in Fig. 2.

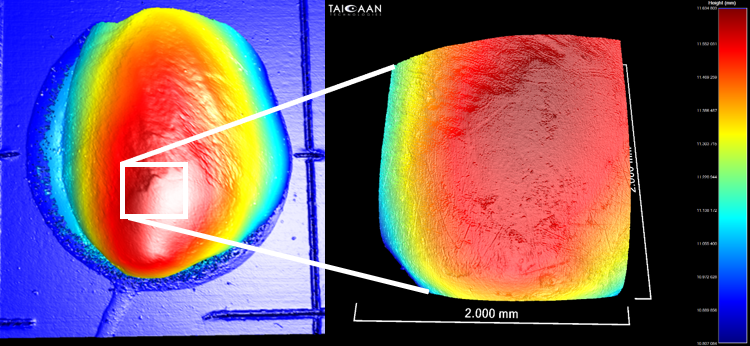

XYRIS reference measurement

As baseline, Fig.3 shows the corresponding measurement collected using the TaiCaan Technologies XYRIS 2020 H confocal scanning system.

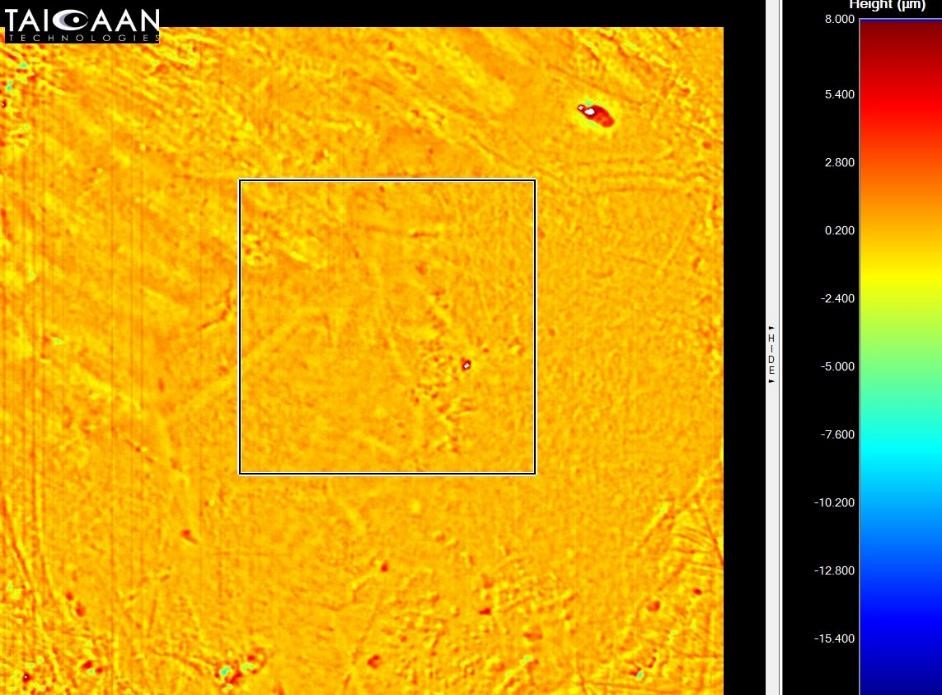

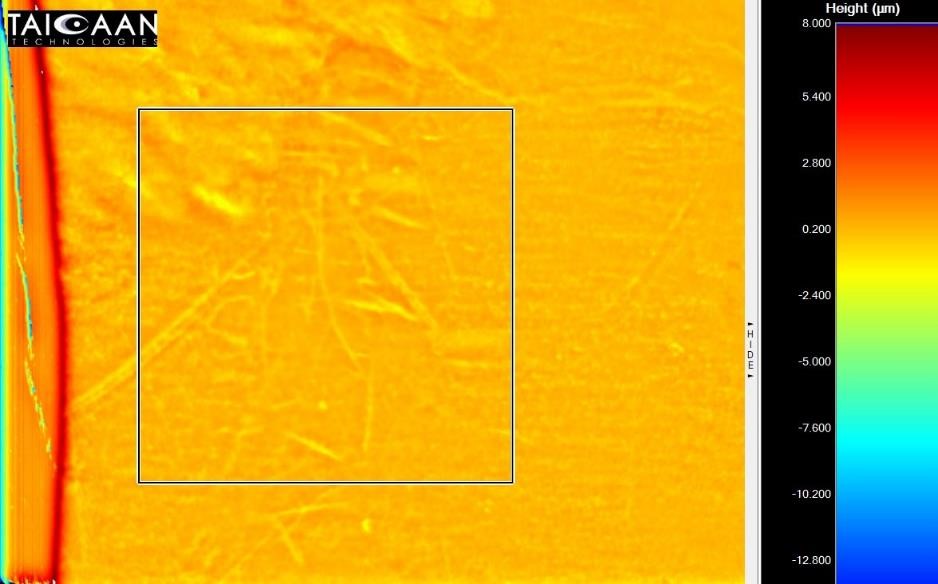

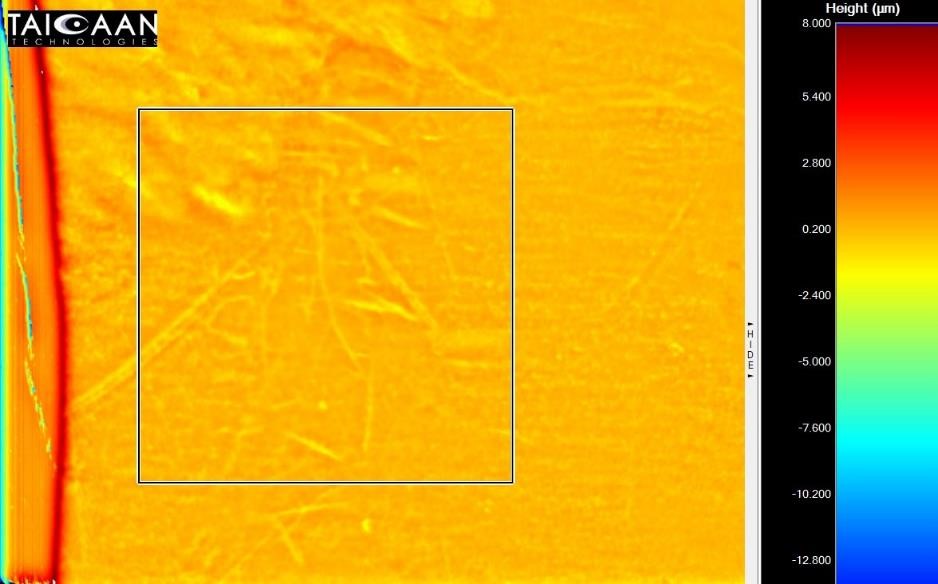

XYRIS 2020H and BEX processed XCT surfaces after Gaussian filter

The use of the BEX toolbox for XCT data is described in a YouTube video; BEX Tutorial 15 – Surface Roughness from 3D STL Data – Part 1 of 2 – Pre-processing the data: https://www.youtube.com/watch?v=gJvNSRBgVlE.

The two surfaces are shown to have a similar roughness for the region in Fig 4, Sa = 0.39 µm and for the XCT data in Fig 5, Sa = 0.22 µm, a more detailed scientific analysis is provided in https://taicaan.com/publications/.

This application note shows how BEX can be used with XCT data to measure sub-micron surface roughness on natural dental surfaces. Please contact us to get a free copy of BEX.