INTRA ORAL DENTAL SCANNER ACCURACY

In this application note ISO Standard defined artefacts of typical restorative dental geometries are measured using the TaiCaan XYRIS H Surface Profiler to produce Ultra High Resolution Digital Surfaces for the calibration of Intra Oral Scanners

- The development of the Intra Oral Scanner (IOS) allow tooth, gum and existing prosthesis to be digitally reproduced by optical scanning (Digital Dentistry) without the use of traditional impression materials

- Advantages – reduced acquisition time, reduced patient discomfort, faster manufacture of prosthesis

- Disadvantages – inaccuracy in the measurement – technique and operator

- The Problem – Understanding the magnitude and location of the measurement errors

- The Solution – the use of a calibrated standard to assess the accuracy and reproducibility of measurements

- TaiCaan Technologies supply Calibrated ISO Standards and digital data for assessing your IOS system measurement performance

The accurate and rapid transfer of the dental morphology record between patient and laboratory has been made possible by the use of dental casting materials. In recent years there has been an attempt to reproduce, enhance and expand on the impression technique through development of the intra oral scanning (IOS).

Intra oral scanners offer the ability to rapidly measure complete tooth and gum surfaces without the use of dental impression materials. This offers advantages to the dental practice in simplifying and reducing clinical procedures times, while minimising patient discomfort.

IOS operates by projecting light from a hand held ‘wand’ inserted into the patients mouth onto the surface of the gums and teeth. The reflected light is captured as a digital point cloud map of the surface and can be reconstructed by software.

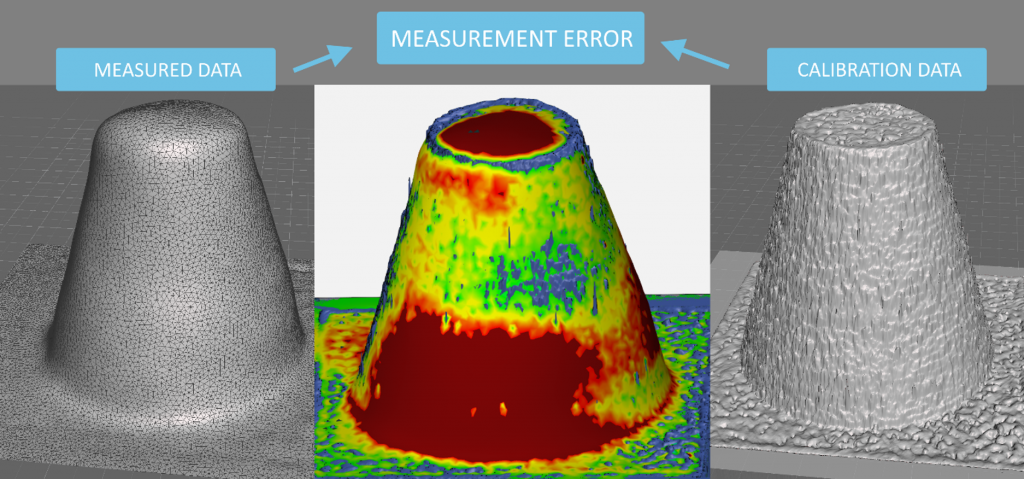

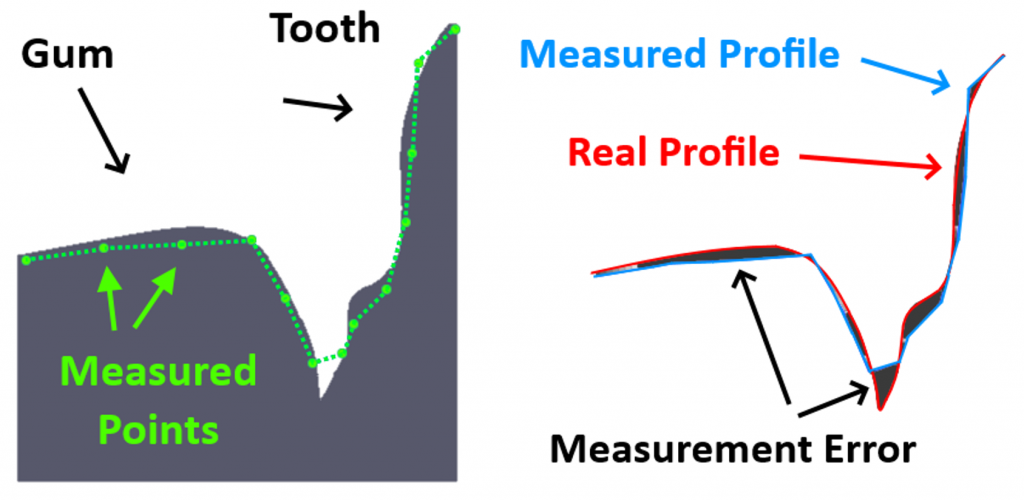

However, the complex nature of the technique and dental surface introduces uncertainty and inaccuracy in the measurement as shown in Figure 1.

Three area of complexity in the measurement using IOS are;

- · The surface reflectivity. This varies measurement performance. Factors such as actual surface material (e.g soft tissues, hard tissues, prosthesis), surface texture or the presence of saliva or blood all influence reflectivity.

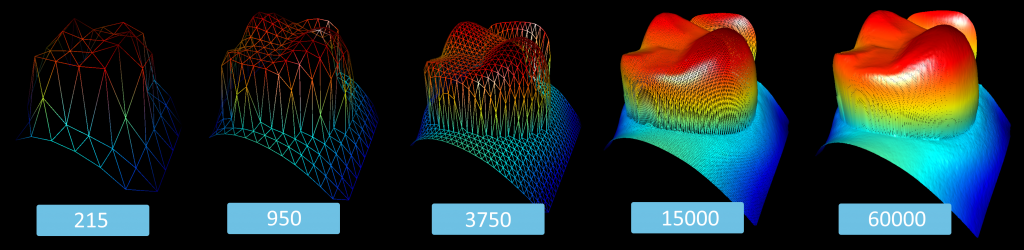

- · The surface generating software used with a IOS system is typically based on a a “best guess” average position from repeat measurements. While this can improve the overall form measurement, detail of the surface is lost.

- · Finally, the clinician operating the device introduces a complex source of variability in the measurement.

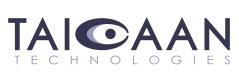

The combination of these errors can lead to poor data, especially at the difficult to measure margins between tooth and gum. The influence of the measurement detail and minor positional errors are shown in Figure 2 and Figure 3.

TaiCaan Technologies specialise in 3-D optical profiling solutions and over the last decade have worked with leading dental research organisations to provide an array of instrumentation, tools and techniques for advanced research into dental wear.

Dental Metrology Standard.

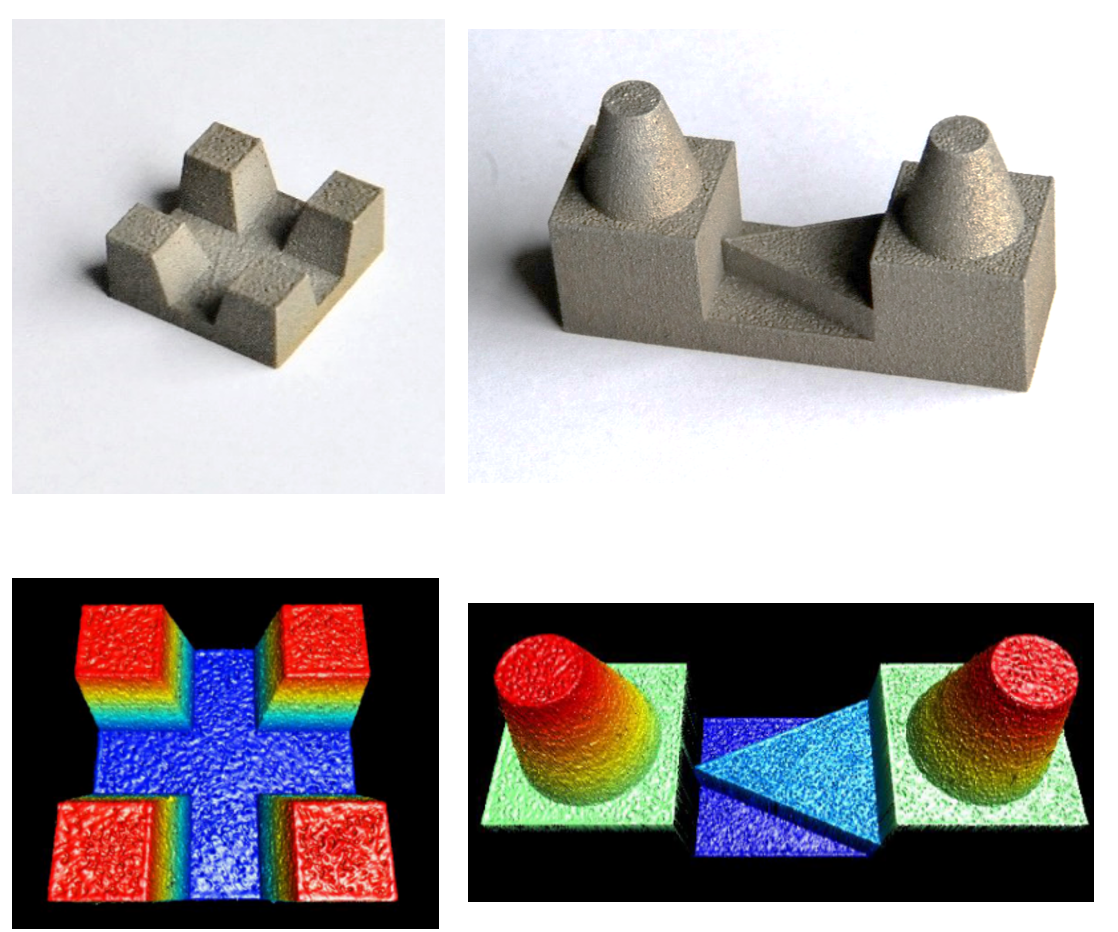

Using advanced manufacturing and measurement techniques we offer a series of calibrated artefacts designed to replicate the complex geometry of restorative dentistry. TaiCaan’s advanced series of XYRIS 2020 Surface Profilers are used to generate traceable calibration of these standards with submicron scale accuracy. Examples geometry of crown inlay and crown bridge preparations are shown in Figure 3, manufactured from laser fused medical grade stainless steel.

The standards provide a reference for IOS measurements that allow measurement error to be quantified and inform the user of the locations of error. By comparison of the IOS digital model obtained to the supplied calibrated model, the location and magnitude of measurement errors can be identified as shown in Figure 5

This measurement of a calibrated standard allows the measurement error to be understood and defined – this offers vital feedback for laboratory technicians preparing prosthesis, and to the clinician on improving their technique.