intra oral dental scanner

- The Application – Development of the Intra Oral Scanner (IOS) allows for the digital reproduction of the tooth and gum interface through optical scanning (Digital Dentistry) without the use of traditional impression materials.

- The Problem – Understanding the magnitude and location of the measurement errors.

- The Solution – the use of a calibrated standard to assess the accuracy and reproducibility of measurements.

- TaiCaan Technologies supply Calibrated ISO Standards for assessing your IOS system measurement performance.

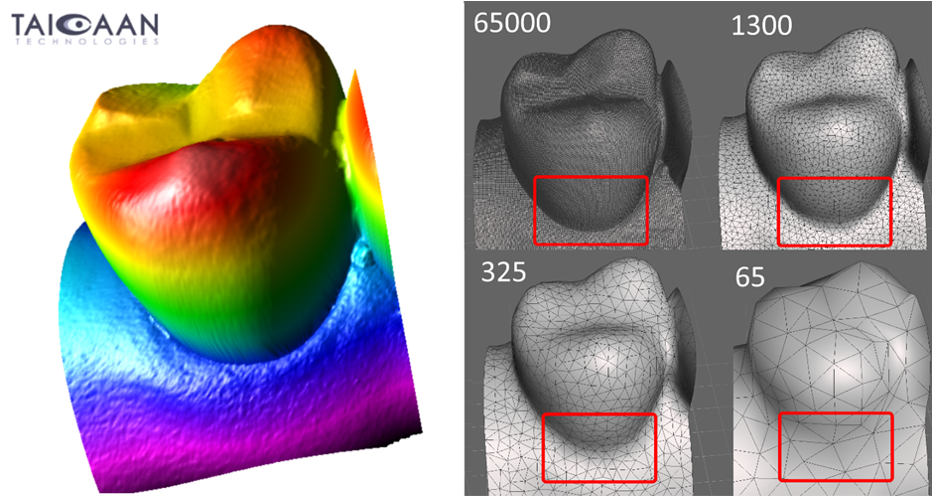

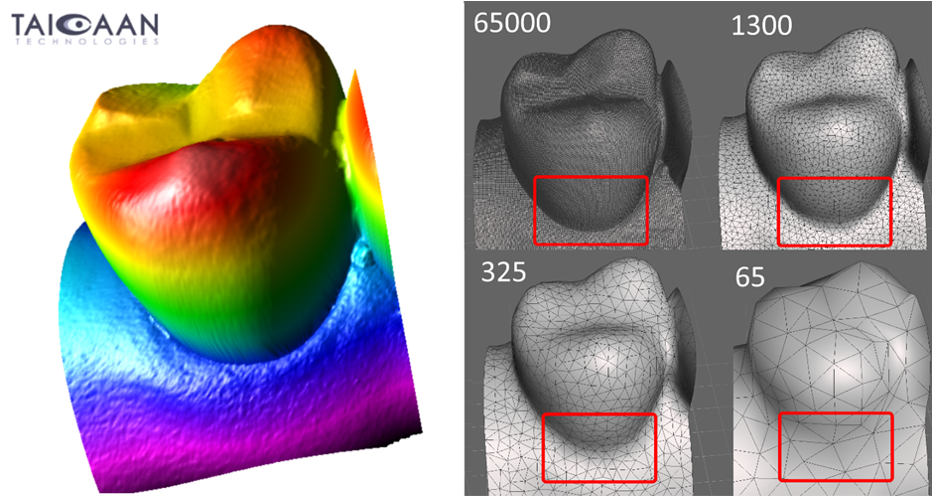

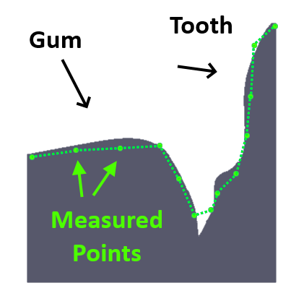

Figure 1. A measurement of a dental impression mould with the number of measurement points in the data (white text) and the definition of the gum/tooth margin region (red box).

Introduction

Intra oral scanners (IOS) offer the ability to rapidly measure complete tooth and gum surfaces without the use of dental impression materials. IOS operates by projecting light from a hand-held ‘wand’ inserted into the patients mouth onto the surface of the gums and teeth. The reflected light is captured by sensors and a digital point cloud map of the surface is reconstructed by software. Photogrammetry is increasing used to optically scan dental impressions.

The IOS systems and some optical scanners introduce uncertainty and inaccuracy in the measurement. Particularly for regions such as the edges at the interproximal regions and gingival margins which may be vital for well-fitting prosthesis. The influence of the number of measurement points can be seen in Figure 1. There are important issues around variation in optical performance (errors) on soft tissues, hard tissues, prosthesis, different surface textures, the operator and the presence of saliva or blood. The combination of errors can lead to poor data, especially at the difficult to measure margins between tooth and gum as shown in Figure 2.

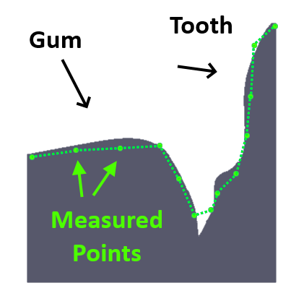

Figure 2 – The result of minor IOS measurement errors (green dots) and interpolation between measurement points (left image – green dotted line) cause volumetric errors (right image – black regions) that are maximum where the surface angle changes rapidly – such as the margins between tooth and gum.

Calibration Standard Artefact

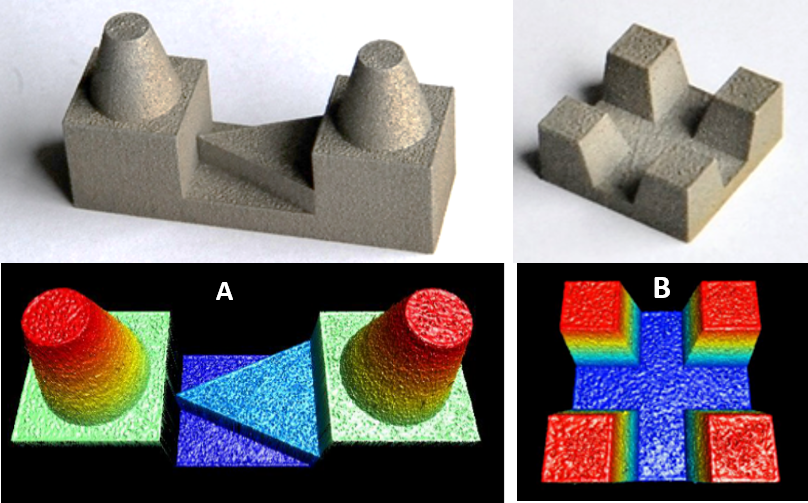

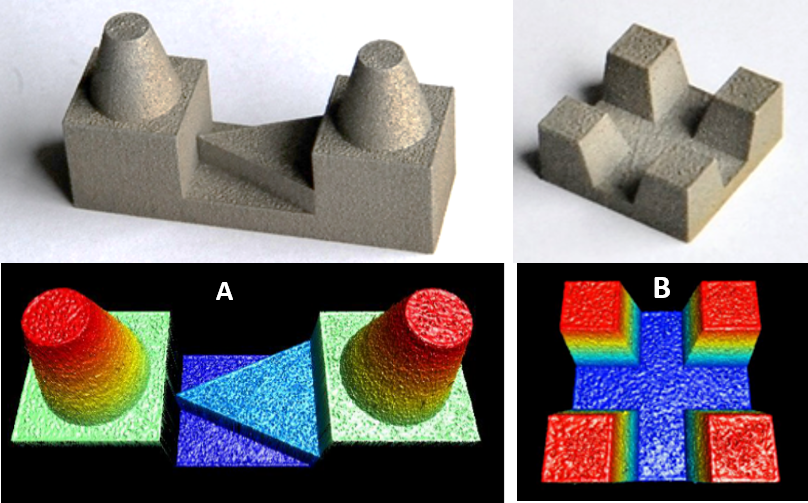

TaiCaan Technologies have over the last decade worked with leading dental research organisations to provide an array of instrumentation, tools and techniques for advanced research into dental wear. XYRIS Surface Profilers are used to generate traceable calibration of standards as shown in Fig.3. The standards provide a reference for IOS measurements that allow measurement error to be quantified and inform the user of the locations of error. By comparison of the IOS digital model obtained to the supplied calibrated model, the location and magnitude of measurement errors can be identified.

Figure 3 – TaiCaan Calibrated standards of restorative dentistry artefacts with ultra-high resolution 3D data using a calibrated XYRIS 2020H. Manufactured analogues representing a crown & bridge preparation (A) and inlay cavity (B). XYZ positional point accuracy of 0.1 µm.

Further Technical information can be provided on request.